Русский

English

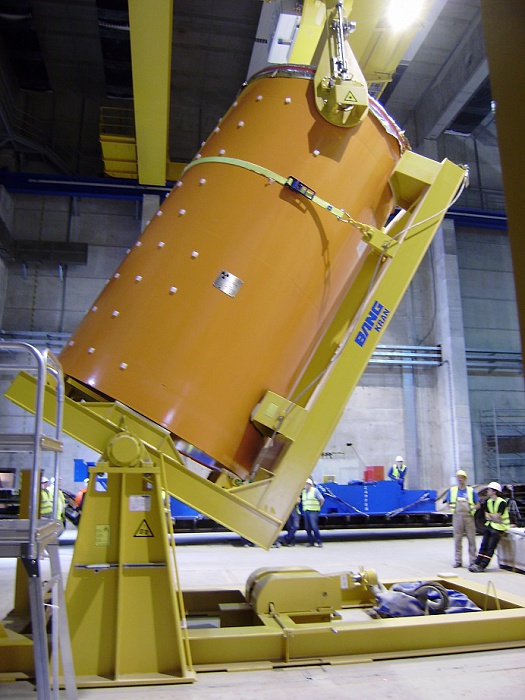

Testing at solid radioactive waste treatment and storage facility at Ignalina NPP, Lithuania

13.10.2017

According to Vice-President of JSC ASE EC Grigoriy Sosnin, the B234 Facility is a unique complex which allows to extract, sort, treat and store SRW depending on their activity levels. The Facility allows to extract, sort and pack waste suitable for burying at the landfills, as well as to treat SRW, which is not suitable for burying, with the use of sorting plants and plants for incineration, compaction and cementation. For control over RW, the Facility is equipped with up-to-date RW tracking system. To date, there are no analogs to this treatment facility in the world.

Nukem Technologies acts as a general contractor for the construction of the Interim Spent Fuel Storage Facility (B1) and Solid Radioactive Waste Treatment and Storage Facility (B 2,3,4) at the INPP.

The implementation of this final phase of the B3, 4 project commenced with granting to the INPP of the trial operation license for the Solid Radioactive Waste Treatment and Storage Facility (B 3, 4) issued by the State Nuclear Power Safety Inspectorate of Lithuania (VATESI).

Currently the B1 Facility is in regular operation. Since 2017, the B2 Facility hot tests on extracting solid radioactive waste (SRW) have been successfully carried out. Within the hot tests, SRW was extracted from the temporary storage and then it was sorted, compacted, placed into the containers and forwarded to the interim storage. In the future, this waste will be placed into the repository for short-lived low-active waste (the B19-2 project). According to the schedule, hot tests shall be completed in November 2017. By this time the documents for the following phase will be prepared - VATESI permits on B2 industrial operation is going to be obtained.

The decommissioning of Ignalina Nuclear Power Plant including new Solid Radioactive Waste, Retrieval, Management and Storage Facilities, is financially supported by the Ignalina International Decommissioning Support Fund (IIDSF) managed by the European Bank of Reconstruction and Development (EBRD). The Ignalina International Decommissioning Support Fund is funded by the European Community as well as by Austria, Belgium, Denmark, Finland, France, Germany, Ireland, Luxemburg, Netherlands, Poland, Spain, Sweden, United Kingdom, Norway and Switzerland.

For reference:

NUKEM Technologies GmbH is a German engineering company specializing in rendering services in the field of radioactive waste (RW) and spent nuclear fuel (SNF) treatment, as well as decommissioning of nuclear and radiation hazardous facilities (power reactors, research reactors, commercial reactors and vessel reactors, NFC enterprises). In 2009 JSC ASE acquired 100% of shares of NUKEM Technologies GmbH, which is a subsidiary of NUKEM GmbH uranium trader in Alzenau, Germany.

For reference:

АSE Group of Companies was established within the framework of development of Rosatom engineering division, by uniting three leading companies of the industry: JSC ASE EC, JSC “Atomstroyexport”, JSC “Atomenergoproekt” and JSC “ATOMPROEKT”. (JSC ASE EC - Atomstroyexport JSC - Atomenergoproekt JSC - ATOMPROEKT JSC)

ASE is one of the global leaders in nuclear power engineering and holds 30% of the global NPP construction market.

ASE has representative offices, branch offices and operational offices operating in 15 countries around the world, with almost 80% of its portfolio coming from the projects abroad.

Besides the company also provides services in the field of NPP decommissioning, construction of facilities for RAW and SNF management, research reactors, thermal power plants as well as a full range of EPC, EPC(M) and PMC services for any complex engineering assets. ASE company develops and implements an innovative Multi-D project management system in the area of complex engineering objects construction which allows more efficient budget, time frame and quality management.

The company is headed by Valery Limarenko, President of the Company, Doctor of Economics.

Company websites: www.niaep.ru; www.atomstroyexport.ru; www.aep.ru; www.atomproekt.com; wwwnukemtechnologies.de